Work we carried out in 2008

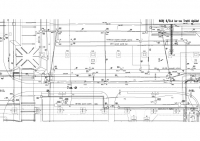

MOL Plc. DANUBE REFINERY – Demolition and replacement works in the hydrocracking and the grounds of the Hydrogen Factory-3 plant

The design task was carried out at the MOL Plc. Danube Refinery. It became timely for the preparation for the new hydrocracking and hydrogen factor plant, which resulted in the necessity of demolition tasks. The plan of the demolition was prepared on behalf of Polygon-TETA Ltd.

Included in the demolition:

- all steam pipes to be found in the area (with the exception of building´s 1st floor power supply);

- the building´s 1st floor power supply was included as part of the second phase of the demolition;

- the demolition of the transformer building´s elevated steam input pipes, marked 669;

- demolition of the deep running No. DN80 steam pipes running parallel between the No. 62 band pipe and the barrack building´s No. 1 pipe.

The task was carried out with "traditional" tools, with 2D design processing, with solutions provided for the demolition planning of the pipes, isometrics and the drawing of TIE-IN points.

The planning for the 2008th were carried out at the beginning of the construction was successfully completed.

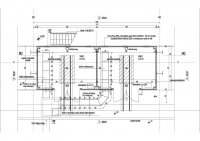

ISD DUNAFERR Ltd. Hot rolling mills – planning work for the modification of the crane supply systems design

The planning exercise was carried out in ISD Dunaferr Rolling Mill Ltd´s plant. Amongst the general design tasks included those belonging to two-piece 2.5 MVA rated outputs, the 10/0.4 kV transformer installation, implementation of the 0.4 kV crane supply systems, the need for transformer booths and development of the switch controls. The general planning was completed based on the design of the IGN Montivo Ltd.

Amongst our tasks included:

- transformer housing development;

- control room development, with the necessary building engineering and power supply;

- cable pit design;

- temporary 2 x 2.5 MVA power 10/0.4 kV transformer installation, later with permanent power input;

- a total of 6 x 400 V crane main power supply distributors, distributor planning.

The drafting and preparation of the Government 382/2007. (XII. 23.) of the authorization plan documentation in accordance with the regulations.

Our company has simplified the burdensome process of obtaining construction permit.

We solved the task with "traditional" tools, with 2D planning of known cost breakdown.

The planning was carried out at the end of 2008. The execution was postponed because of the economic crisis.

MOL Plc. DANUBE REFINERY – Jumper cable fitting to the HDS torch cables

The design task was carried out in the MOL Danube Refinery. For the torch marked 184, plants GOK-3 and BEK-5 had used a shared torch feeder pipe. In order to ensure that the BEK-5 plant could be shutdown, it was necessary to modify pipeline joints. A connection had to be designed for the current torch feeder pipeline system to the HDS torch feeder pipes. We carried out the design in accordance with that of Polygon-TETA Ltd.

The connection was provided through two parallel running torch feeder pipes (9.0 - 12.0 m high) between them. The vertical span between the wires was 2.5 - 3.0 m. The distance measured from each other was 4-5 m.

The connecting pipes included two shut-off assembly lines, a drain valve and a sampling valve. Amongst the technical tasks included inspection of the torch capacity from the perspective of ensuring that both plants could be shutdown simultaneously.

The documentation plans were prepared in accordance with the regulations of the MKEH, taking into account the 63/2004. (IV. 27) GKM regulatory amendment.

We solved the task with "traditional" tools, with 2D design processing, with technical flowchart diagrams, pipeline plans, steel framework plans and the known costs breakdown.

The planning was carried out in the summer of 2008, with the construction successfully completed.